INTRODUCTION

SMART-1, the European Space Agency's Small Mission for Advanced Research and Technology is currently on its way to the moon and carries aboard AMIE - the Asteroid and Moon Imaging Experiment. AMIE intends to image the moon in the full visible spectrum and in three dedicated spectral regions with a single camera. Significant system complexity and weight reductions can be demonstrated. The challenge became to create a special filter, which could be placed in front of a camera and would split the transmitted light in different spectral regions through predefined sub-areas. This was passed by

ESA's SME Initiative to German company

Optische Interferenz Bauelemente GmbH Jena (OIB), with the award of a contract to develop the technology.

FUNDED ACTIVITIES

At the same time, this focal plane filter required that the various sub-areas have equal optical thickness, in order to enable high-definition imaging of the lunar surface. These requirements can only be met by providing thin-film multi-layer systems applied to both sides of a glass substrate, with the sub-areas touching with an accuracy of a few micrometers (urn). The required edge definition accuracies exceeded the limits of the state of the art.

In order to meet this challenge,

OIB opted for a cooperation that would bring together the innovative capabilities of two german SMEs:

1.

OIB would manufacture the thin-film interference systems with the desired spectral functions,

2.

Supracon AG Jena was charged with manufacture of coating masks with suitable edge definition quality.

In the coating process the generation of oxide layers via preliminary generation of chemically different hydroxide layers is used, which are converted into oxides after removal of the coating masks. This was the decisive step to enable the thin-film deposition to occur at lower temperatures and, thus, the use of the mask technology. The masks were made according to the well-known lift-off technology with the process steps being necessarily adapted to the thin-film optical technology requirements. Through close co-operation of the two companies it was possible to successfully develop and implement a process for the manufacture of focal plane filters completely meeting the predetermined requirements.

Fig. 1 shows the edge definition quality of adjacent sub-areas of the FPFM filter. The bold strip represents the 8 µm wide overlap region of two adjacent 38-layer optical coatings stacks.

The thin strip shows the 2 µm wide filter edge of the optical coatings. Each of the thin-film coating systems has a total thickness of 4.7 µm.

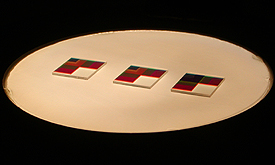

Fig. 2 shows three complete focal plane filters illuminated with transmitted light, each filter with the dimensions 15×18×1 mm showing seven segments with different optical functions.

The complete filter consists of a total number of 314 optical layers arranged laterally and stacked on each other.

TECHNOLOGY & APPLICATIONS

The technology for the manufacture of these high performance patterned spectral filters was successfully tested and demonstrated to

ESA. The results showed excellent reliability, and the decision was taken to incorporate the filters into the AMIE camera.

One of the objectives of the SMART-1 spacecraft is to image the moon with a view to answering the question of its origins. The current hypothesis is that the Moon is the result of a colossal collision with Earth in its early history. If the theory is correct, then the Moon should contain less iron than the Earth, proportionally to lighter elements such as magnesium and aluminium. By gauging the relative amounts of chemical elements comprehensively for the very first time, SMART-1 can make a distinctive contribution to this momentous scientific issue.

SMART-1's ultra-compact electronic camera, AMIE will enable scientists to study afresh the Moon's topography and surface texture. It measures light with a million pixel points in a field of view 5 degrees wide. The FPFM divides this field in a clear area without filter and the three filter areas that allow it to select the deep red and three short infrared spectral bands. By looking at selected regions from different angles, and under different lighting conditions, AMIE will provide new clues about its chemical composition and geological history, helping us understand how the lunar surface has evolved.

Instruments and techniques to be tested in examining the Moon from SMART-1, including AMIE, will later help

ESA's BepiColombo spacecraft to investigate the planet Mercury.

FUTURE PERSPECTIVES

The trend towards miniaturization in optical measuring technology has lead to a new generation of measuring devices. These devices allow completely new applications to be opened to the optical measuring technology. While in earlier years the bulky equipment was operated stationary, requiring samples to be delivered to the device, portable equipment itself new is enabled to come to the object to be measured.

Miniaturization of these devices, as a consequence, has driven the standards of optical component manufacturing.

OIB believes that their innovative procedure meets many of the new challenges. They have already identified two promising applications:

Patterned pre-selectors for CCD line spectrometers

Transfer of optical mask patterns for spectral analyzers in optical network technology

Both applications stand to benefit from the use of high performance patterned spectral filters, and the technological procedures developed in cooperation between

O.I.B. GmbH Jena and

Supracon AG Jena.

INFORMATION CONTACT POINT

Mr. Eberhard Schmidt

O.I.B. GmbH Jena (D)

E-mail: e.schmidt@oib-jena.de

Telefon: +49-3641-357890

Fax: +49-3641-357891

www.oib-jena.de

« back

Contact us

Supracon AG

An der Lehmgrube 11

07751 Jena

Germany

Tel.: +49-3641-2328100

Fax.: +49-3641-2328109

info(at)supracon.com